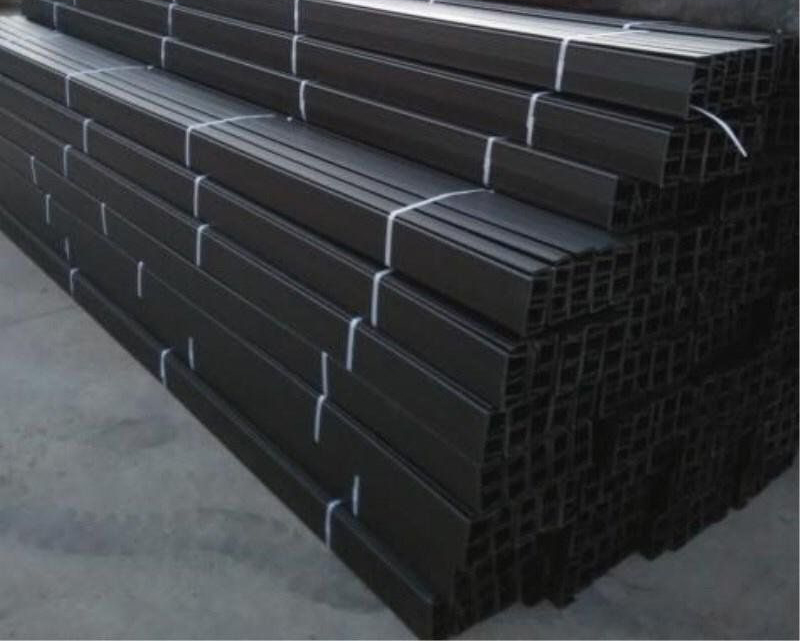

HDPE E-Lock / Poly Lock

Securing Geomembrane liner to concrete structures can be carried out either by mechanical fastening (using stainless steel flat bar, neoprene sponge and anchor bolts) method or by embedding E-Lock into concrete and Geomembrane liner is then welded onto the exposed surface of E-Lock using extrusion welding method.

ENVIRO ENGINEERS provide E-lock in different shapes and custom length to suit the actual project requirement. All E-lock are made from virgin HDPE resin with 2 to 3% carbon black content. E-lock are made from the grade of resin normally used by major Geomembrane manufacturers for make HDPE Geomembrane liner. The advantages of using E-lock against mechanical fastening are cheaper in cost, easier to install and more secured.

Welding Rod (Extrusion Rod)

The field installations are performed by certified field technicians and constitute a crucial step in ensuring optimal system performance. Since Geomembrane cover large surface areas, several rolls are usually required on site. Therefore, rolls need to be assembled together using special equipment such as hot wedge and extrusion welding machines, the latter being fed by what we call welding rod. Welding rod needs to be manufactured from the same raw materials used in the manufacturing of Geomembrane. Our welding rod are available in the following range:

- Material: HDPE

- Diameter: 4.0 mm or 5.0 mm

- Color: Black